BENEFITS

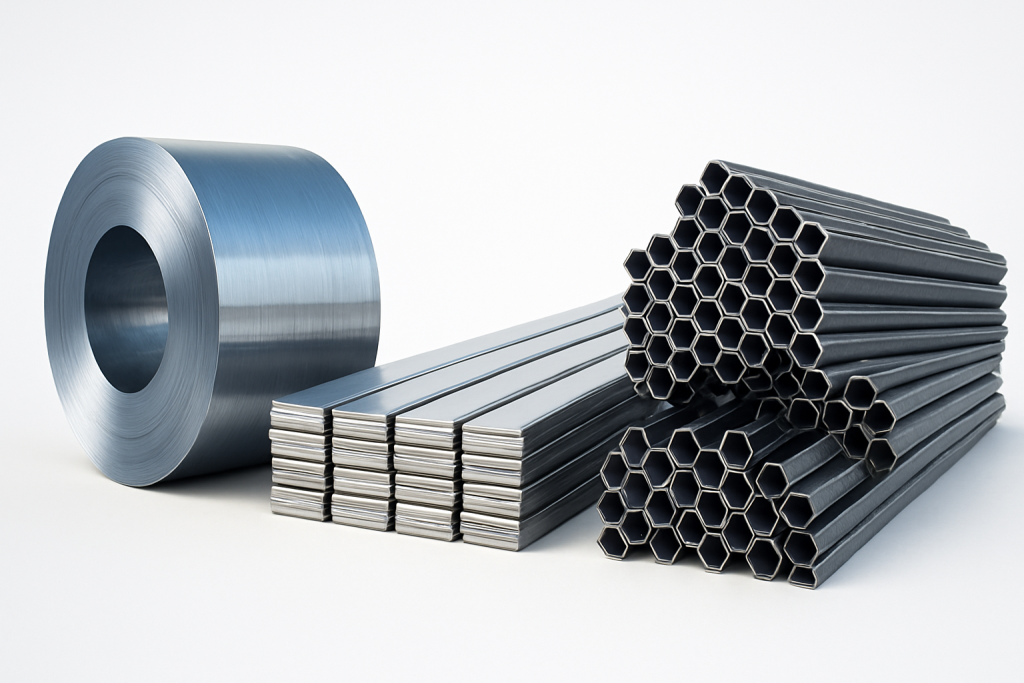

Hot Rolled Coils are fundamental to industrial production across the globe. Known for their strength, malleability, and cost-efficiency, they serve as a versatile base material across construction, transportation, and manufacturing. Their ability to withstand extreme processing conditions makes them a staple for heavy-duty applications that demand structural integrity and adaptability.

FEATURES

Produced through high-temperature rolling, HRC exhibits a rougher surface finish and broader dimensional tolerances than cold-rolled steel. However, this also allows for greater ductility and ease in fabrication. These coils are available in a variety of thicknesses and widths, and they support secondary processes such as pickling, galvanizing, or forming, depending on end-use requirements.

APPLICATIONS

HRC is widely used in the fabrication of storage tanks, steel frames, railway and metro systems, automotive chassis, wind tower components, heavy-duty agricultural equipment, shipping containers, and industrial machinery. It serves as a starting point for further processing into cold-rolled and coated products.

BENEFITS

Cold Rolled Coils offer excellent surface finish, precision tolerances, and enhanced mechanical strength, making them ideal for applications requiring a refined aesthetic or exact specifications. Their high dimensional accuracy allows for superior performance in automated production lines, forming processes, and fine engineering.

FEATURES

Manufactured at room temperature using high-grade hot rolled coil as input, CRC undergoes controlled rolling and annealing, resulting in improved surface quality and tighter thickness tolerances. Available in deep-drawing and structural grades, CRC supports coating, painting, and stamping operations.

APPLICATIONS

Commonly used in the manufacturing of home appliances, automotive body panels, electrical cabinets, steel drums, precision tubes, and shelving systems. CRC is also the preferred substrate for producing galvanized and pre-painted steel products.

BENEFITS

Galvanized steel extends the service life of structural and fabricated products by providing corrosion resistance in outdoor and moisture-prone environments. It eliminates the need for frequent maintenance, making it a cost-effective solution for long-term performance in harsh conditions.

FEATURES

Produced by hot-dipping cold rolled coil in a bath of molten zinc (GI) or zinc-aluminum-magnesium alloy (GL), galvanized steel offers a continuous metallic coating that adheres strongly to the base metal. Options include chromate-free, skin-passed, and anti-fingerprint finishes depending on end-use.

APPLICATIONS

Widely used in the construction of roofing panels, rainwater goods, HVAC ducting, fencing systems, automotive parts, prefabricated housing structures, electrical enclosures, and agricultural equipment. It’s a primary choice in utility infrastructure exposed to the elements.

BENEFITS

PPGI and PPGL offer a ready-to-use, aesthetic solution with excellent weather resistance. The pre-painted surface minimizes finishing work at the fabrication stage, reduces coating costs, and ensures color consistency, making it ideal for branded and visible installations.

FEATURES

These coils are coated with high-performance paints such as polyester, silicon-modified polyester (SMP), or PVDF over a GI or GL base. Available in custom colors, gloss levels, and embossing textures. Resistant to UV degradation, chemical exposure, and flaking.

APPLICATIONS

Used extensively in industrial cladding, roofing sheets, insulated sandwich panels, garage doors, warehouse walls, signage, and commercial facade systems. PPGI/PPGL is also employed in cold storage and container production where clean aesthetics and durability are essential.

BENEFITS

Structural steel provides strength, rigidity, and load-bearing capacity essential for constructing industrial and civil infrastructure. Its predictable performance and design versatility enable engineers to optimize for both safety and cost-efficiency across a range of applications.

FEATURES

Available in standard shapes such as I-beams, H-beams, L-angles, T-sections, and U-channels. Manufactured according to global standards like ASTM, EN, and JIS, structural steel is available in various thicknesses, lengths, and load ratings, including high-yield grades for demanding applications.

APPLICATIONS

Foundational in bridges, industrial warehouses, high-rise buildings, offshore platforms, steel-framed factories, airport terminals, and large-scale energy projects. Also used for load-bearing supports, mezzanine frames, and heavy equipment bases.

BENEFITS

Reinforcement bars and wire rods enhance the tensile strength of concrete structures, ensuring stability and load distribution across bridges, foundations, and tunnels. Their ability to bond with concrete makes them essential for modern reinforced design.

FEATURES

Rebar is available in deformed and plain types, typically produced in cut lengths or coils, and conforms to standards such as ASTM A615 or BS 4449. Wire rod is produced in coils with controlled diameters and chemistry, ideal for secondary drawing and shaping

APPLICATIONS

Rebar is integral to reinforced concrete for use in residential, commercial, and infrastructure construction. Wire rods are drawn into welding wire, nails, fencing, wire mesh, and high-strength spring steel for industrial equipment.

BENEFITS

DSAW and LSAW pipes offer robust pressure-handling capability and dimensional stability over long distances, making them the preferred option in energy transmission and large-diameter fluid transport systems.

FEATURES

Fabricated using submerged arc welding, these pipes are available in high wall thickness and large diameters, suitable for onshore and offshore projects. LSAW pipes feature straight seams, while DSAW (including spiral welded versions) support flexible project requirements.

APPLICATIONS

Used in crude oil and gas pipelines, district heating networks, industrial water supply lines, bridge piling, and structural columns for high-load applications. Common in energy, petrochemical, and infrastructure sectors.

BENEFITS

Stainless steel delivers a unique combination of hygiene, corrosion resistance, and aesthetic quality, making it ideal for chemically aggressive and cleanroom environments. Its strength-to-weight ratio and recyclability add sustainability value to industrial use.

FEATURES

Available in 200, 300, and 400 series with finishes like 2B, BA, No.4, and mirror polish. Resistant to acids, bases, and chlorides, stainless steel is easy to fabricate and weld. Comes in sheets, coils, tubes, and bar stock.

APPLICATIONS

Utilized in pharmaceutical plants, food processing equipment, desalination facilities, chemical storage tanks, marine structures, hospital furnishings, and clean energy systems such as hydrogen storage and solar mounting components.